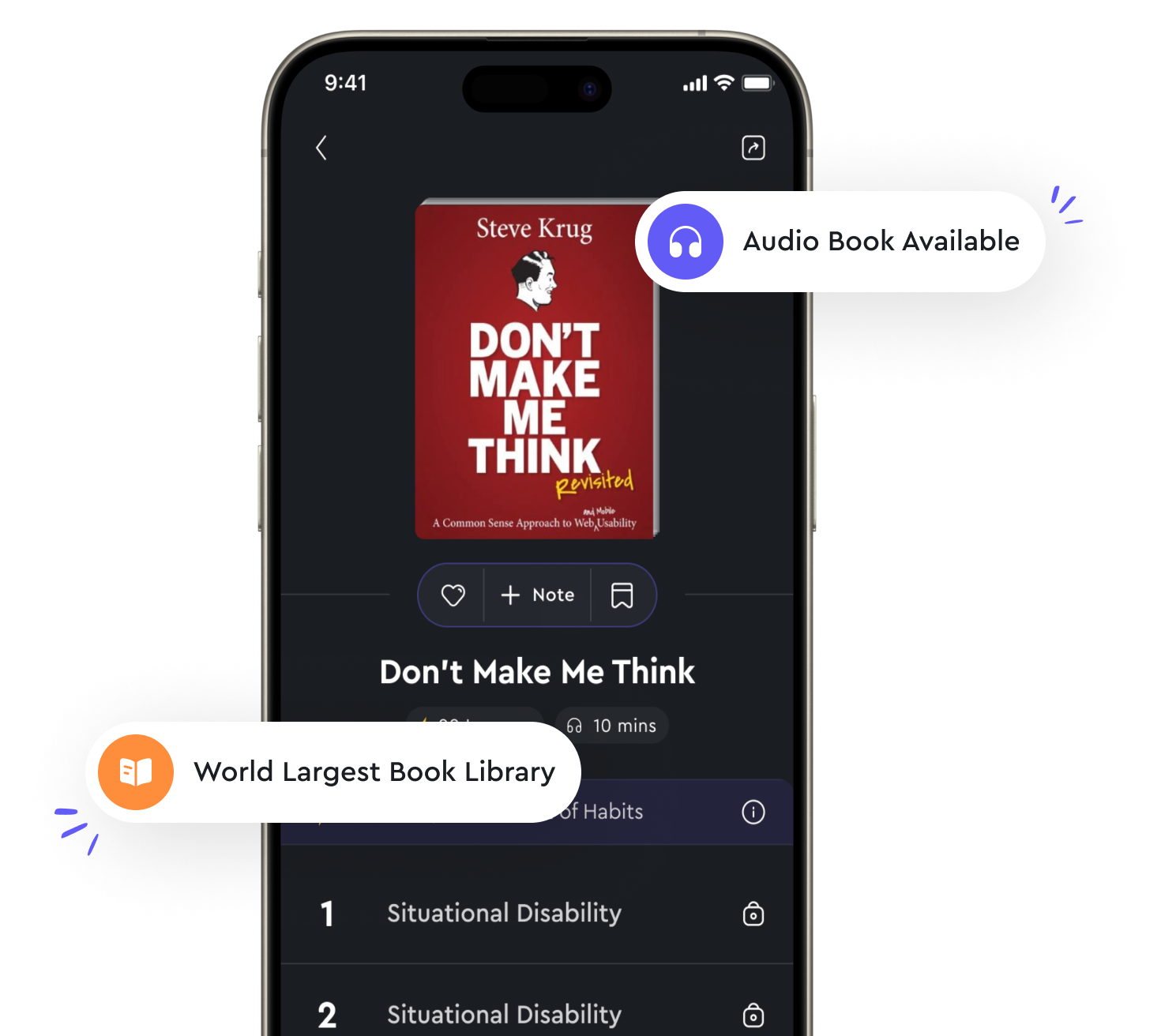

Audio available in app

Materials science informs the selection and use of materials in structural design from "summary" of Structures by J. E. Gordon

Materials science plays a crucial role in the field of structural design by providing valuable insights into the properties and behavior of materials under various loading conditions. Engineers rely on materials science to make informed decisions about selecting the appropriate materials for a given structural application. By understanding the physical and mechanical properties of materials, engineers can optimize the performance and durability of structures while ensuring safety and reliability. The selection of materials in structural design is not arbitrary but is based on scientific principles and empirical data. Materials science helps engineers evaluate the strengths, stiffness, ductility, and other key properties of materials to determine their suitability for specific structural components. For example, in designing a bridge, engineers must consider factors such as the weight of the traffic, environmental conditions, and material fatigue to select the most appropriate materials for the bridge deck, beams, and columns. Furthermore, materials science provides insights into how materials behave under different loading conditions, such as tension, compression, shear, and torsion. Engineers use this knowledge to predict how materials will deform, crack, or fail when subjected to various forces, allowing them to design structures that can withstand the expected loads and forces without compromising safety or performance. In addition to material selection, materials science also informs the use of materials in structural design. Engineers must consider factors such as fabrication processes, joining techniques, and material compatibility to ensure that the chosen materials can be effectively incorporated into the overall design. For example, welding, bolting, or adhesive bonding may be used to join structural components made from different materials, and engineers must understand how these processes affect the structural integrity of the final assembly.- Materials science serves as a foundation for structural design, providing engineers with the knowledge and tools necessary to make informed decisions about material selection and use. By applying the principles of materials science, engineers can design structures that are not only strong and durable but also efficient, cost-effective, and environmentally sustainable.